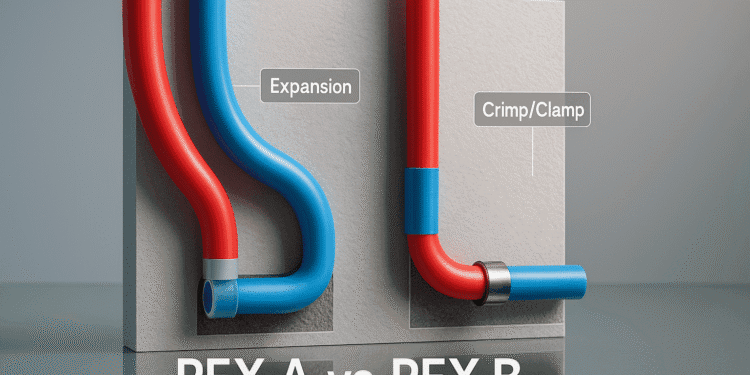

PEX A vs PEX B: Understanding the Key Differences

Introduction to PEX Plumbing

Have you ever wondered why your plumber raves about PEX tubing? Cross-linked polyethylene, commonly known as PEX, has revolutionized the plumbing industry over the past few decades. This flexible plastic tubing has become the go-to choice for residential water supply lines, replacing traditional copper and CPVC pipes in countless homes.

But here’s where it gets interesting: not all PEX is created equal. When you start shopping for PEX tubing, you’ll quickly discover there are different types, with PEX A and PEX B being the most popular options. Understanding the differences between these two can save you money, time, and potential headaches down the road.

What is PEX A?

PEX A represents the premium tier of cross-linked polyethylene tubing. The “A” designation refers to the manufacturing method used to create the cross-linking in the polyethylene molecules. This type is produced using the Engel method, also known as the peroxide method, where cross-linking occurs during the manufacturing process at high temperatures.

What makes PEX A special? It boasts the highest degree of cross-linking among all PEX types, typically achieving around 80-89% cross-linking. This superior cross-linking gives PEX A its distinctive characteristics: exceptional flexibility, superior shape memory, and remarkable resistance to kinking. When you hold PEX A tubing in your hands, you’ll immediately notice how supple and forgiving it feels compared to other options.

What is PEX B?

PEX B takes a different approach to achieving cross-linking. This variety is manufactured using the silane method, also called the moisture-cure method. In this process, the polyethylene is exposed to a silane compound, and cross-linking occurs after the tubing is extruded when it’s exposed to hot water or steam.

PEX B typically achieves cross-linking levels between 65-70%, which is lower than PEX A but still provides excellent performance for most plumbing applications. It’s slightly stiffer than PEX A, which some installers actually prefer for certain applications. The manufacturing process for PEX B is less expensive, which translates to a more budget-friendly price point for consumers.

Manufacturing Methods: The Core Difference

The Peroxide Method (PEX A)

The peroxide method creates PEX A through a fascinating chemical process. Manufacturers add organic peroxide to the polyethylene before it’s shaped into tubing. As the material is extruded and exposed to high temperatures (often exceeding 200°C), the peroxide breaks down and creates free radicals. These free radicals form cross-links between the polymer chains, creating that tight molecular structure that gives PEX A its superior properties.

This method is more complex and requires precise temperature control throughout the manufacturing process. Think of it like baking a delicate soufflé—the conditions need to be just right to achieve that perfect result. The investment in this sophisticated process is why PEX A commands a premium price.

The Silane Method (PEX B)

The silane method offers a more straightforward manufacturing approach. Silane compounds are grafted onto the polyethylene molecules, and then the material is extruded into tubing shape. After extrusion, the tubing is exposed to hot water or steam in a curing process that can take several days. During this curing period, the silane groups react with moisture to form cross-links between the polymer chains.

This method is like marinating meat—you’re adding the ingredients first and letting time do its magic. The slower, post-extrusion cross-linking process makes PEX B manufacturing more economical, but it also results in a slightly different molecular structure compared to PEX A.

Flexibility Comparison

Which is More Flexible?

When it comes to flexibility, PEX A takes the crown without question. Its higher degree of cross-linking creates a tubing that bends with remarkable ease. You can make tight turns and navigate around obstacles with minimal effort. PEX A can typically bend to a radius of about 5-6 times its diameter without kinking or crimping.

PEX B, while still flexible compared to rigid piping materials, is noticeably stiffer. It requires a bend radius of approximately 6-7 times its diameter. This difference might not sound significant on paper, but in practical applications—especially in cramped spaces—that extra flexibility can be a game-changer.

Installation in Tight Spaces

Have you ever tried threading a pipe through a narrow space between floor joists or behind cabinets? This is where PEX A’s superior flexibility really shines. Its ability to snake through tight spaces and make sharp bends without special fittings makes it ideal for retrofit applications and complex installations.

PEX B, being less flexible, sometimes requires additional fittings or more creative routing to navigate tight spaces. However, its stiffer nature can actually be an advantage when you need the tubing to hold its shape or span longer distances without support.

Memory Properties

Shape Memory in PEX A

Here’s one of PEX A’s most impressive features: it has exceptional shape memory. What does this mean in practical terms? If you accidentally kink PEX A tubing during installation, you can often restore it to its original shape using a heat gun. The high degree of cross-linking allows the molecular structure to “remember” its original form and return to it when heated.

This property also makes PEX A incredibly forgiving if it freezes. The tubing can expand to accommodate ice formation and then return to its original dimensions when thawed, significantly reducing the risk of burst pipes in cold climates.

PEX B’s Limited Memory

PEX B doesn’t possess the same shape memory capabilities as PEX A. Once you kink PEX B, it generally stays kinked. While you might be able to improve it slightly with heat, you won’t achieve the same recovery as with PEX A. This means you need to be more careful during installation to avoid creating permanent deformations.

That said, PEX B’s stiffer nature means it’s less prone to accidental kinking in the first place when handled properly. It’s a trade-off: less flexibility but also less susceptibility to installation errors if you’re working carefully.

Cost Considerations

Price Point of PEX A

Let’s talk money—because that’s often the deciding factor for many homeowners and contractors. PEX A is the more expensive option, typically costing 20-40% more than PEX B. This premium price reflects the more sophisticated manufacturing process and the superior performance characteristics.

For a typical residential plumbing project, this price difference could translate to several hundred dollars in material costs. However, many professionals argue that the ease of installation and reduced risk of installation errors can offset the higher material cost through reduced labor time.

Price Point of PEX B

PEX B offers excellent value for budget-conscious consumers. Its lower manufacturing costs translate directly to savings at the checkout counter. For large projects or situations where the superior flexibility of PEX A isn’t critical, PEX B provides reliable performance at a more accessible price point.

Many contractors choose PEX B for new construction projects where routing is straightforward and the additional flexibility of PEX A isn’t necessary. The cost savings can be substantial on large-scale projects without sacrificing quality or longevity.

Long-term Value Assessment

When evaluating cost, think beyond the initial purchase price. Consider the total installation cost, including labor and fittings. PEX A’s flexibility might reduce installation time, and its expansion fittings create slightly larger flow paths. PEX B’s lower material cost might be offset by the need for more fittings in complex installations.

Both types offer decades of reliable service when properly installed, so the long-term value equation really depends on your specific application and installation conditions.

Installation Requirements

Tools Needed for PEX A

PEX A is typically installed using the expansion method, which requires a specialized expansion tool. This tool looks like an oversized pair of pliers with different-sized heads for various pipe diameters. You’ll also need expansion fittings, which are designed specifically for this method.

The expansion tool isn’t cheap—professional-grade models can cost several hundred dollars. However, once you have the tool, the installation process is straightforward. You expand the tubing, insert the fitting, and the tubing contracts around it, creating a secure, reliable connection. No clamps, no crimping—just expand and insert.

Tools Needed for PEX B

PEX B offers more flexibility in connection methods. You can use crimp fittings, which require a crimping tool, or clamp fittings (also called cinch clamps), which use a separate clamping tool. These tools are generally less expensive than expansion tools, making PEX B more accessible for DIY enthusiasts and contractors just starting with PEX installations.

The variety of connection options also means you can choose the method that best fits your comfort level and budget. Crimp tools are reliable and widely available, while clamp systems offer easy visual inspection of proper installation.

Learning Curve for DIYers

If you’re a do-it-yourself homeowner, which system is easier to master? Both have their advantages. PEX A’s expansion method is intuitive—expand, insert, done. There’s less that can go wrong, and the connections are very forgiving of minor installation variations.

PEX B’s crimp or clamp methods require more precision. You need to ensure the crimp ring is properly positioned and compressed to the correct specification. However, these methods have been around longer, so there’s more instructional content available, and the lower tool cost makes it easier to get started.

Durability and Longevity

When you’re investing in your home’s plumbing system, you want it to last. Both PEX A and PEX B are designed for long-term service, with manufacturers typically offering 25-year warranties. In real-world conditions, both types have demonstrated the ability to last 50 years or more when properly installed and maintained.

The higher cross-linking density in PEX A theoretically provides slightly better resistance to oxidative degradation and environmental stress cracking. However, in practical applications, both types perform exceptionally well. The key to longevity with either type is proper installation, avoiding exposure to UV light, and protecting the tubing from physical damage.

Neither PEX A nor PEX B corrodes or scales like metal pipes, and both resist the buildup of minerals in hard water. They’re also resistant to the chemical treatments commonly used in municipal water systems, including chlorine.

Freeze Resistance

How PEX A Handles Freezing

Living in a cold climate? PEX A’s freeze resistance is legendary among plumbers. While no pipe is completely freeze-proof, PEX A’s exceptional flexibility and shape memory give it remarkable resistance to freeze damage. When water inside PEX A freezes and expands, the tubing can expand up to three times its diameter without bursting.

Once the ice thaws, PEX A returns to its original shape thanks to its shape memory properties. This doesn’t mean you should intentionally let PEX A freeze—frozen pipes can still cause flow problems and potential splitting at fittings—but it provides an extra safety margin in extreme weather conditions.

How PEX B Handles Freezing

PEX B also handles freezing better than rigid piping materials like copper or CPVC, but it doesn’t quite match PEX A’s performance. PEX B can expand when frozen, but it may not return completely to its original dimensions after thawing. Repeated freeze-thaw cycles are more likely to cause permanent deformation or eventual failure with PEX B than with PEX A.

That said, PEX B still offers significantly better freeze protection than traditional materials. For homes with adequate insulation and heating, or in moderate climates, PEX B’s freeze resistance is more than adequate for reliable service.

Connection Methods

Expansion Fittings for PEX A

The expansion method used with PEX A creates what many consider the most reliable cold-water connection in the plumbing industry. Here’s how it works: you expand both the tubing and potentially the fitting, insert the fitting into the expanded tubing, and as the PEX A contracts back to its original size, it creates a tight, secure connection.

These connections have a slightly larger internal diameter than the tubing itself because the fitting sits inside the pipe rather than the pipe fitting over a barbed fitting. This means better flow rates and fewer pressure drops. The connection is so secure that it’s approved for burying without access panels in many jurisdictions.

Crimp and Clamp Fittings for PEX B

PEX B works with traditional crimp and clamp connection methods. With crimp fittings, you slide a copper crimp ring over the tubing, insert a barbed fitting, and compress the ring using a crimp tool. The compressed ring creates pressure that holds the tubing securely onto the fitting.

Clamp systems work similarly but use a stainless steel clamp instead of a copper ring. These connections are reliable and have been proven over decades of use. The barbed fittings do reduce the internal diameter slightly at connection points, which can affect flow in systems with many fittings, but this is rarely an issue in properly designed residential systems.

Code Compliance and Approvals

Both PEX A and PEX B meet or exceed all major plumbing codes in the United States, including the International Plumbing Code (IPC), Uniform Plumbing Code (UPC), and various regional codes. They’re certified by organizations like NSF International for potable water applications and approved by the International Code Council (ICC).

However, code acceptance can vary by region. Some areas were slower to adopt PEX in general, and a few municipalities still have restrictions or preferences. Before starting any plumbing project, check your local building codes and talk to your local building inspector about any specific requirements or restrictions.

Interestingly, some regions show preferences for one type over another based on local contractor familiarity and historical usage patterns rather than technical superiority. In parts of the Midwest, PEX A dominates, while other regions show stronger PEX B adoption.

Best Applications for Each Type

When to Choose PEX A

PEX A is your best choice when you’re dealing with challenging installation conditions. Retrofit applications where you’re snaking pipe through existing walls, complex layouts with numerous bends, or installations in extremely cold climates all favor PEX A. Its superior flexibility and freeze resistance justify the premium price in these situations.

If you’re a professional plumber who values installation speed and reliability above all else, PEX A’s forgiving nature and expansion fittings can reduce callbacks and installation time. The investment in expansion tools pays off over multiple projects.

PEX A is also ideal when you want the best possible freeze protection, such as for outdoor applications, unheated spaces, or vacation homes that might experience temperature extremes.

When to Choose PEX B

PEX B shines in new construction projects with straightforward routing where its lower flexibility isn’t a limitation. The cost savings become more significant on larger projects, and the variety of connection options provides flexibility in installation methods.

For DIY homeowners on a budget, PEX B offers an excellent entry point into PEX plumbing. The lower cost of both materials and tools makes it more accessible, and the proven reliability means you’re not sacrificing quality for affordability.

In commercial applications where straight runs are common and installation conditions are more controlled, PEX B’s performance characteristics are perfectly adequate while keeping project costs manageable.

Common Misconceptions

Let’s clear up some myths about PEX plumbing. First, some people believe PEX B is inferior quality because it’s less expensive. This isn’t true—it’s simply manufactured differently. Both types meet the same performance standards; they just excel in different situations.

Another misconception is that you can use any connection method with any type of PEX. While some overlap exists, PEX A is specifically designed for expansion fittings, and using crimp fittings with PEX A doesn’t take advantage of its superior properties. Conversely, PEX B shouldn’t be used with expansion fittings as it lacks the shape memory to contract properly.

Some folks worry that all PEX will leach chemicals into drinking water. Both PEX A and PEX B are certified for potable water use and have been extensively tested for safety. While all materials leach something initially (even glass and copper), PEX leaching rates drop to negligible levels quickly and remain well below safety standards.

Finally, there’s a myth that rodents can’t chew through PEX. Unfortunately, rodents can damage any type of plastic pipe, including both PEX A and PEX B. Proper installation in areas protected from rodent access is important for all types of plumbing.

Conclusion

So, which is better—PEX A or PEX B? The honest answer is: it depends on your specific situation. PEX A offers superior flexibility, exceptional shape memory, and the best freeze resistance, making it ideal for challenging installations and extreme conditions. Its premium price reflects these advanced characteristics and the sophisticated manufacturing process.

PEX B provides excellent performance at a more accessible price point, making it perfect for straightforward installations and budget-conscious projects. It’s proven its reliability over decades of use and offers multiple connection options that many installers prefer.

Your choice should consider your installation conditions, budget, climate, and personal preferences. If you’re tackling a complex retrofit in a cold climate and want the absolute best performance, PEX A is worth the investment. If you’re plumbing new construction with straightforward routing in a moderate climate, PEX B offers outstanding value.

Remember, both types will provide decades of reliable service when properly installed. The most important factor isn’t which type you choose—it’s ensuring proper installation following manufacturer guidelines and local building codes. Whether you go with PEX A or PEX B, you’re choosing a modern, reliable plumbing solution that outperforms traditional materials in many ways.

FAQs

Q1: Can I mix PEX A and PEX B in the same plumbing system?

While it’s technically possible to use both types in the same system, it’s generally not recommended. Each type requires different fittings and installation methods, which can lead to confusion and potential installation errors. Stick with one type throughout your system for consistency and to avoid having to maintain two different sets of tools and fittings. If you’re adding to an existing system, match the type already installed.

Q2: How long does PEX tubing really last?

Both PEX A and PEX B are designed to last 50+ years under normal operating conditions. Manufacturers typically offer 25-year warranties, but the actual lifespan often exceeds this significantly. The key factors affecting longevity include proper installation, water quality, operating temperatures, and protection from UV light. Many early PEX installations from the 1980s are still functioning perfectly today, suggesting these systems can easily last the lifetime of a home.

Q3: Is PEX safe for drinking water?

Yes, both PEX A and PEX B are certified safe for potable water by organizations like NSF International and meet all EPA standards. They undergo rigorous testing for chemical leaching, and studies show that any initial leaching drops to negligible levels within the first few weeks of use. PEX has been used in European drinking water systems since the 1970s and in North America since the 1980s with an excellent safety record.

Q4: What’s the best way to prevent PEX from freezing?

Prevention is always better than relying on freeze resistance. Insulate PEX pipes in unconditioned spaces, maintain adequate heat in your home, and consider heat tape for particularly vulnerable sections. If you’re leaving a home vacant in winter, drain the plumbing system or maintain minimum heating. While PEX A can survive occasional freezing better than other materials, no pipe should be regularly subjected to freezing conditions—prevention protects all types of plumbing and ensures reliable operation.

Q5: Do I need special tools to work with PEX, and are they expensive?

The tools required depend on which type you choose. PEX A requires an expansion tool, which typically costs $150-$400 for professional-grade models, though battery-powered versions can exceed $1,000. PEX B can use crimp tools ($40-$150) or clamp tools ($30-$100), making it more accessible for DIYers. All these tools are one-time investments that last for many projects. For small jobs, some home centers offer tool rental programs, allowing you to try PEX installation without the full tool investment upfront.

Please don’t forget to leave a review.